Meeting the Challenges of a One-Kilometer Tower

- AS+GG

- Mar 5, 2013

- 14 min read

Originally published CTBUH Journal

by Peter Weismantle and Alejandro Stochetti

Kingdom Tower in Jeddah, Saudi Arabia, will be the tall building to go where no building has gone before – beyond 1,000 meters. For the first time, the team at Adrian Smith + Gordon Gill Architecture discuss at length the process that went into designing a one-kilometer-tall tower, as well as specific details about the structure and configuration.

Introduction

During the spring of 2009, Adrian Smith + Gordon Gill Architecture began working on a prototype of a mile-high tower. With an eye to the future, AS+GG’s interest was to understand the potential and challenges of creating a tower that was substantially higher than the tallest man-made structure at that time, the 828-meter Burj Khalifa. The questions were: How do we get to a substantially taller building? Is there a new typology? What about elevators? What about structure? And, above all, what about daily life in such a building The exercise turned out to be not merely theoretical. AS+GG was then invited to participate in a competition to design the world’s new tallest tower at a height of at least one kilometer. The location was Jeddah, Saudi Arabia, and it would be the centerpiece of a master plan that would cover an area of 5.3 million square meters. The invitation was also extended to other international architectural firms, including Foster + Partners, Pelli ClarkePelli, Kohn Pedersen Fox, Pickard Chilton andSOM. The competition brief asked teams to design a multi-use tower serving a five-star hotel, serviced apartments, and office and residential units. The proposed design would take Kingdom Tower to the highest position in CTBUH’s three categories for maximum heights;firstly, it would have the highest occupied floor(currently, Burj Khalifa Level 154 at 584.5 meter).Secondly, it would achieve the highest architectural top (currently Burj Khalifa at elevation 828 meter). Lastly, it should have the highest tip (also currently Burj Khalifa at a height of 829.8 meter). The design competition was scheduled to last one month, after which a winner would be announced.

It is important to note that one of the criteria for the winning scheme was the tower’s “constructability potential and efficiency.”

The Competition Entry

With Kingdom Tower, the goal was to advance the innovations of Burj Khalifa and discover what could be done better. The team also knew what had worked very well on the Burj, and which could be taken into account in the design.

One of the earliest studies done, leading to the overall form (see Figure 1), shows part of the process that helped to create the tower’s final massing configuration. One of the original challenges was to build extremely tall without adding too much area to the final building. The competition brief called for 290,000 square meters gross floor area (GFA) for the tower and podium. The diagram illustrates how for the original competition program area a simply extruded square plan would not reach a significant height. The next drawings show how going from square to circle to triangular form helped, but not enough. The following diagrams show how the tapering of such shapes extended the potential height of the tower. Finally, for a variety of reasons, the tapered “Y” shaped plan was chosen. As a further step toward reaching greater heights,the carving applied at the balcony areas removed GFA from typical floors and pushed it further up.These design decisions helped to provide the client, Jeddah Economic Company, with a streamlined, highly performative design (see Figure 2).

Supertall Buildings and Wind

The Y-shaped plan forming the base of the design offered several advantages. A 120-degree separation between wings allows for views to be expansive but not directed toward adjacent units, which would have created privacy issues. A Y-shaped plan would provide a higher ratio of exterior wall to internal area, which would maximize the residential units’ views and exposure to light (see Figure 3).

The “Y” shape also allowed the spreading of the base of the tower without increasing the depth of the lease-span. This means that the building can still maintain a reasonable 10:1 height to width ratio without having a large amount of unusable deep internal space. The “Y” shape also helps develop a clean and simple structural diagram in which every element participates in both gravity and lateral support. If one considers the shape as being similar to a wide flange beam with its mass of structural material at the end of each wing (the “flanges”) where it is most optimally placed, connected by shear walls (the “webs”)forming the corridor walls and core, the structural efficiency is maximized by placing the material where it will do the most good in resisting wind-induced bending loads. The triangular core thus formed by the shear walls is also an optimized shape, very good at resisting wind induced torsion. Lastly, the unique nature of the Y-shaped plan and structure allows for certain serendipitous results. Having three legs, the plan naturally has at least three stairs, creating an immediate redundancy. With its continuous, reinforced concrete shear walls, those stairs are completely enclosed within a very robust and secure environment, again enhancing that aspect of the life safety system of the tower.Furthermore, these very thick shear walls provide more than the minimum required fire separation and are a very effective sound control mechanism between public corridors and private residential spaces (see Figure 3).

Early on, it was also decided that the tower could not just be vertically extruded. Had that approach been pursued, wind vortices would have become organized on the sides of the tower and amplified the effect, inducing accelerations of lateral movement well above advisable levels as these amplified vortices approach the resonant frequency of the tower. To counter this natural magnification,one very typical approach is to reduce the plan size of the tower as it rises in height. OnBurj Khalifa, the tower has 27 tiers with setbacks/plan shape reductions at each.Similar to Burj Khalifa, Kingdom Tower“confuses the wind” by reducing the cross sectional size of the tower as it rises. However unlike Burj Khalifa, Kingdom Tower does it by means of a continuous taper to each wing(see Figure 4). A continuous taper was a result of one of the primary lessons learned in the construction of Burj Khalifa. Eliminating the stepped setbacks as on the Burj obviated the need for outrigger transfers and belt trusses at certain locations, which in turn will reduce the concentration of structural loads as well as permit a more efficient, continuous, and uninterrupted construction process.Furthermore, having different rates of taper to each wing results in different termination heights for each, thereby creating the dramatically distinct three part spire of Kingdom Tower. This intuitive concept was confirmed by wind studies performed by RWDI at its facility in Toronto.

The structure for the Kingdom Tower is comprised entirely of cast-in-place reinforced concrete walls, coupling beams, and conventionally reinforced flat plate concrete floor framing (see Figure 5). The structure contains no outriggers or wall/column transfers. Due to the continuous and uninterrupted vertical nature of the walls for the tower, a highly efficient jump form system can be utilized. Form work for the floor slabs also can be reused due to the highly repetitive geometry of the tower. The faces of the shear walls are all vertical, with the exception of the ends of each wing, which taper to follow the form of the Tower. This can be accomplished by a simple shift of between 200 and 300 millimeters for each 4 meters vertical lift or internal block outs in form work that is lifted vertically. Because the ends of the shear walls slope, the taper at the end of each wing is created by a consistent 3.5 meter cantilever extension of the slab edge. All building envelope notching is achieved by simply dropping off slab edge cantilevers.

Through this concept of dropping off structural components to create the architectural expression, and allowing form work to easily jump up on each level of the tower, a highly efficient and constructible system is realized while creating a very distinctive form.

Concrete compressive cube strengths required to realize the tower structure are not expected to exceed 115 MPa, and 60 to 80 MPa at significant heights. Advances in concrete mix designs and concrete pumping technology will be brought to bear in order to place high strength concrete in the upper portions of the tower.

The foundations for the tower are a raft supported on bored circular piles located approximately 2.5 meters below existing grade due to site modifications raising the base of the tower (see Figure 6). This modification minimizes the amount of potential dewatering required on the site during construction of the lower levels.

Tower Form, Culture, Site, and Location

As part of a performative design process, any solution should reflect a specific culture, location and time:

In the case of Kingdom Tower, the solution reflects the desire of Jeddah Economic Company (JEC) and the leaders of Saudi Arabia to show the world the potential of their vision of the Kingdom as an increasingly important, vital, and thriving member of the international community. It is also rooted in the desert landscape. The sleek, streamlined form of the tower can be interpreted as a reference to the folded fronds of a growing young desert plant. The way the fronds sprout upward from the ground as a single form, then start separating from each other at the top, is an analogy of new growth fused with technology. As AS+GG partner Gordon Gill explains: “the tower evokes a bundle of leaves shooting up from the ground – a burst of new life that heralds more growth all around it. This symbolizes the tower as a catalyst for increased development around it.”

In terms of the project’s location, studies of sun, wind and views, among many others parameters, informed and guided the design process that shaped the tower. The tower orientation in plan was adjusted to point one wing toward Mecca, while another points almost directly north, by which both the overall solar load was reduced while simultaneously improving the views of the majority of residential units (see Figure 7). As it turned out, that adjustment in orientation also helped mitigate the magnitude of pedestrian level winds in several of the more critical locations, although it slightly increased the overall load due to design wind conditions. Regarding “time,” Kingdom Tower uses current technologies and materials, but also incorporates “future-making” designs. In the field of vertical transportation, for example, the height and program requirements will be a challenge that elevator manufacturers have accepted in agreeing to develop what will be the world’s tallest multi-deck elevator. In a similar vein, the location and height of the towers’ mechanical floors will push the technology of the buildings’ chilled water, sprinkler, and domestic systems and equipment with their limits to working pressure and capacity.

Plan Shape and Unit Planning

Stair location plays an important part in the overall efficiency and fluidity of the plan potential. The architects wanted to make sure that a simple and continuous open plan could be preserved, to allow for units to be located fluidly and efficiently, with minor interruptions. Stairs are thus located at every wing end, allowing for a very open plan. This move also allows for the major structural elements to wrap around the stairs, creating a series of super-structural tubes (see Figure 8).Wing ends are a very critical part of the plan and massing because they contain a major structural and vertical circulation element. But they are also needed to allow for an open corner view. For that reason, a minimum of three meters of vision glass is allowed along the wing ends throughout the height of the tower.

Entrances to units are allowed via typical penetrations through the corridor wall.

Balconies in a Supertall Building

The inclusion of balconies in this type of building is not very common. However, the Kingdom design includes balconies for a variety of reasons. First, weather conditions in Jeddah are tolerable or even pleasant for a substantial part of the year. At the highest levels of this tower, reduced air temperatures and increased wind speeds make outdoor conditions better than at lower levels. A balcony is an important amenity in the marketing of a luxury residential unit. Secondly, at a latitude of 21.5 degrees and with the prevailing sunlight intensity, any horizontal projection will create shadows on the tower surface, reducing direct solar radiation. Thirdly, from the tower massing point of view, the overlapping pattern of the balconies added a layer of intricacy and visual complexity to this mostly vertical structure (see Figure 9). The horizontally overlapping balconies visually tie the tapering wings together and add to the “organic” character of the structure. Lastly, and as mentioned above, the subtractive process that brings out the balconies removes areas from typical floors that can be added to higher units, in line with the client’s goals.

Overall Tower Section and Stacking

The competition design entry can be seen as three tapered wings terminating at different heights with angular ends tied together with an array of horizontal elements such as the balconies and mechanical floors. To some viewers it might seem a complex composition, and even difficult to build. But the goal was to ensure that the building was fairly simple and cost-effective to build. With this in mind, different construction companies and component fabricators were consulted early in the process to make sure the assumptions were correct.

One of the key elements for addressing the constructability issue is the ability to extend the concrete and climbing form as high and as continuously as possible, having no transfers. In that regard, concrete vertical walls go up uninterrupted until they stop. There are no additional columns at the end of each wing. One of the main structural components is the stair enclosure, which also goes up uninterrupted until it stops. Overall, the vision was that concrete should be used as high in the structure as possible. The goal was to remove, if possible, any additional steel member at the top.

Another significant design decision early on was to standardize the floor-to-floor height at four meters for all uses, including office, residential, and hotel. Among other things, this would help elevatoring flexibility and potential change in tower stacking through the different design stages.

In agreement with the client, office floors are placed at the bottom to take advantage of larger floor plans and dropping elevator bays. These are followed by hotel, serviced apartments, and residential units of different levels. At the very top, is placed a superpent house to allow the tenant to be at the crown of the tallest building in the world.

Exterior Wall

The exterior wall or cladding represents a significant portion of the total investment in a building of this type. In order to maintain costs, a simple, repetitive, easily erected system needed to be designed. To meet these goals, from the initial design it was agreed that there would be only one primary, unitized wall type on the tower. The simple panel design allows for early procurement as well as permits tenders from multiple manufacturers. Establishing a consistent vertical module (4 meters) and horizontal module (1.5 meters) allows for repetition of identical panels. Repetition of identical panels facilitates assembly line type mass production. The ends of each tapered wing are planar and, except for the corners, consist of identical panels over the entire height. The angle of each taper has been designed to relate to the horizontal module, permitting a repetition of the “make-up” unit over the height of the tower. The typical 4 by 1.5 meter panel size permits loading into materials hoists and does not require use of tower cranes. Special areas such as mechanical floors, sky lobbies, etc., utilize variations of the typical panel. The typical curtain wall is designed to a high performance criterion, that includes thermally broken aluminum frames, high-performance insulating glass, and extensive areas of insulated spandrel glazing. Although the tower looks like a fully glazed building, the overall vision glass to spandrel area ratio is actually 50:50.

Maintenance was also an issue. In the Middle East – in particular, cities in Saudi Arabia such as Jeddah – preventing sand dust collection and the need to clean the façade periodically is an important challenge. Any surface exposed to the atmosphere will be exposed to dust collection. In response, the goal is to prevent and limit the amount of exterior wall surfaces at the macro level by reducing the overall amount of exterior wall and, at a micro level, by limiting or eliminating the use of projected elements off the glass surface. With these and other considerations in mind, the Kingdom Tower exterior wall evolved into an extremely streamlined surface with no projected elements, which will make it easier to maintain and clean. In addition, this will reduce to a minimum the materials needed for construction, reducing costs and embodied carbon. Reducing the potential for collecting dust, however, does not eliminate the need to provide a façade access system.As was utilized on Burj Khalifa, the system utilizes proven, tried and tested, state-of-theart technology. The system is designed to completely wash the windows and clean the exterior wall at least four times a year. Multiple façade access units of various types are required to cover the more than 166,000 square meters of cladding. Having multiple units allows for redundancy and enhanced reliability. Furthermore, the system is designed, and machines are sized, to permit glass unit replacement.

The Evolution of the Design

Overall, the design competition entry, submitted in July 2009, was mostly intact in its most significant elements at the end of the Schematic Design phase in February 2010.The evolution and adjustment of the scheme were mostly focused on the following elements:

Overall Massing and Stacking

A series of massing studies was carried out to maximize area program distribution throughout the height of the tower. The objective was to increase the size of the floor plates toward the top and reduce it at the bottom. From the developer’s point of view, more saleable area on the most expensive floors was important. Geometrically speaking, the taper of each of the wings was modified and rotated around one-third of the tower, moving the wing walls further out and higher up, and moving them in at the lower floors. The original competition scheme showed an additional tapered profile, connecting canopies to the main tower body, making office floors larger. This move was eliminated, reducing office floor area and overall tower area at the lower floors.

Sky Terrace at Level 157

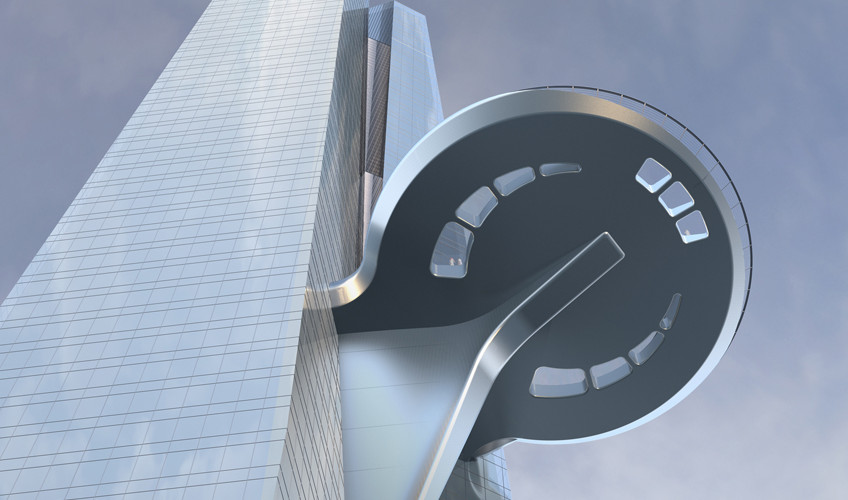

The client asked for the inclusion of a helipad to be mostly used by the owner or visitors of the super-penthouse at level 157. The original design placed it at this level, where it would be the platform from which to access or leave the Majelis (lounge) of the penthouse via helicopter. However, further studies and consultation with experienced helicopter pilots and the wind engineering consultants suggested that the helipad location would make taking off or landing maneuvers extremely dangerous. But by this point, the design for the helipad was integrated and accepted as part of the overall tower design. It was decided that the feature’s new use would be as a “sky terrace” serving Level 157. It will be the highest terrace in the world when completed at an elevation of 630 meters (see Figure 10).

Canopy Evolution

The canopy elements developed from the original competition scheme to schematic design. Softer lines were sculpted and more detailed sun studies were developed to address the required extent of the canopy elements to stop direct solar radiation onto the lobbies’ clear glass cable walls. The final design shows three extended, softly curved canopies that cover the main lobbies and extend horizontally to protect parking ramp entries (see Figure 11). Further development of the canopies’ cladding components was considered and added in the next phase of Kingdom Tower development to address harvesting of concentrated sun rays and their use in energy production.

Conclusion

This paper outlines the structure, sequence, and process that gave shape to the Kingdom Tower design competition winning scheme. It is intended to address the major design decisions and briefly touch on the reasons behind them. The intent of the design process was to channel the cultural, site, and temporal forces in order to create Kingdom Tower, sensitive to the client’s culture and location as well as this pivotal moment in the Kingdom’s history and the history of architecture and engineering.

Designing the world’s tallest building is by its very nature an unprecedented task. It requires an open mind in search of the optimal solution for every challenge, even if it means going beyond the proven and accepted methods, processes, or technologies. Every team involved needs to challenge its past experience and go further. Design architects have in their hands the opportunity to be at the forefront of their profession. As they develop the design, they will face forces that will add risk to the project at every corner. The success of such endeavors will always depend on the clear-minded decision of an ambitious client with the support of a visionary architect and the best teams in every discipline. The contractor will have to work efficiently based on the roadmap traced by architects and consultants and also advance their trade beyond the current norm.

These major ambitious steps have been taken before and they have had unprecedented success. Petronas Tower in Kuala Lumpur, Jin Mao Tower in Shanghai, and Burj Khalifa in Dubai have elevated their cities, countries, and regions to new heights. Projects of the nature of Kingdom Tower will redefine their local and regional environments, will create jobs and opportunities, and will become the central piece of a new urban center (see Figure 12). As such, iconic buildings as Kingdom Tower help to transform and urbanize communities and in doing so, contain suburban sprawl and add to densification with their inherent benefits.

In light of this, the Kingdom Tower design team has agreed to commit to a series of future papers in the CTBUH Journal, intended to address in greater depth each of the fundamental systems and/or challenges involved in the design of a supertall building. Those papers will thus include foundations/ geotechnical engineering, the exterior wall, structure, vertical circulation systems, fire and life safety, wind engineering, MEP systems, and others.

Comments